Solving problems with spot Ag plating

Issue ①: More efficient production of small semi-conductor parts

The expanding global economy has led to increasingly fierce price competition in semi-conductor parts and a high level of competition among semi-conductor part manufacturers. This has led to more efficient production processes which has caused the following issues.

- There are a lot of losses when producing parts from plated materials, making it not possible to decrease costs.

- Plated materials are not compatible with production processes, making it not possible to increase efficiency.

Nishihara Rikoh Solutions

We have had multiple discussions with our customers on making their production process more efficient and proposed the spot silver plating as the optimal solution.

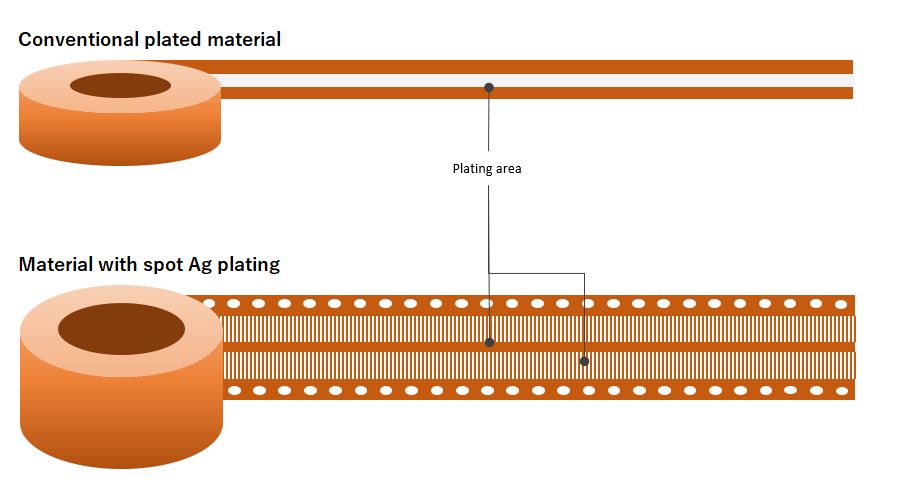

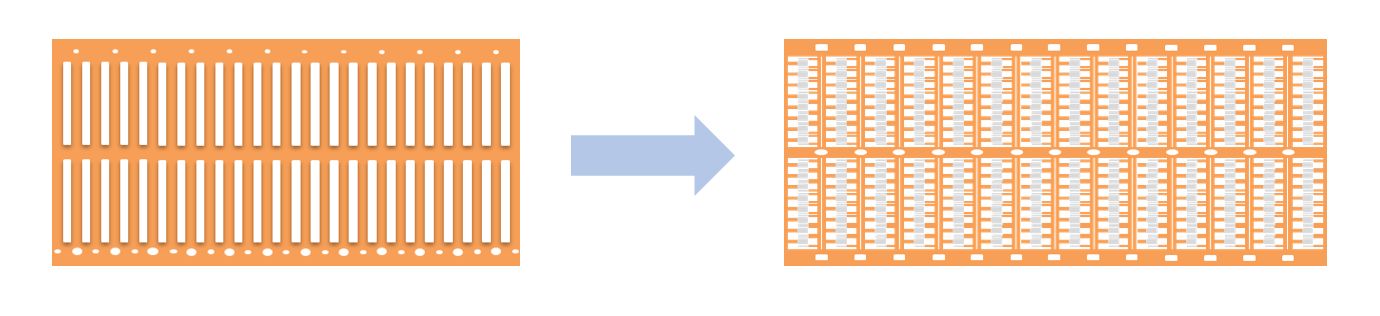

As the following figure shows, switching from conventional plating materials to spot silver plating specifications increased the number of parts which can be produced per unit area of plating materials by 5 times, which decreases material losses.

Spot silver plating with a perpendicular strip pattern layout has great compatibility with the resin sealing process enabling improved efficiency in user production.

Leadframe

| Base material | Finishing | Undercoat | Plating side [㎜] | Minimum Pitch[㎜] | Thickness[㎜] | Width[㎜] | ||

| Plating | Thickness[μm] | Plating | Thickness[μm] | |||||

| Cu,42alloy | Ag (Matte/Semi-bright) |

1~10 | Cu | 0.01~0.5 | 0.8±0.1 | 3 | 0.1~0.8 | 9~75 |

Related Links

We provide hoop plating with stable quality at an inexpensive price.

By controlling the plating area, we optimize the electronic component product process.