Solving problems with N-Ni plating

Issue: Improving fuel efficiency with next generation automobiles

Next generation automobiles are equipped with batteries and use busbars to send electricity from the battery to each unit. Lightweight busbars are necessary for improved fuel efficiency so we are proceeding with the transition to aluminum busbars with nickel plating. The following issues have come up in this transition.

- Aluminum is lightweight but contact electricity resistance is high without nickel plating, making it unsuitable for busbars.

- Nickel plating conventionally deteriorates over time which increases contact electricity resistance.

Nishihara Rikoh Solutions

Welding, conductive adhesive, physical grinding and breaking the oxide film through increasing fastening power and such, are possible solutions for better contact electricity resistance of oxide film in aluminum. However, plating is a popular option when considering long term quality assurance.

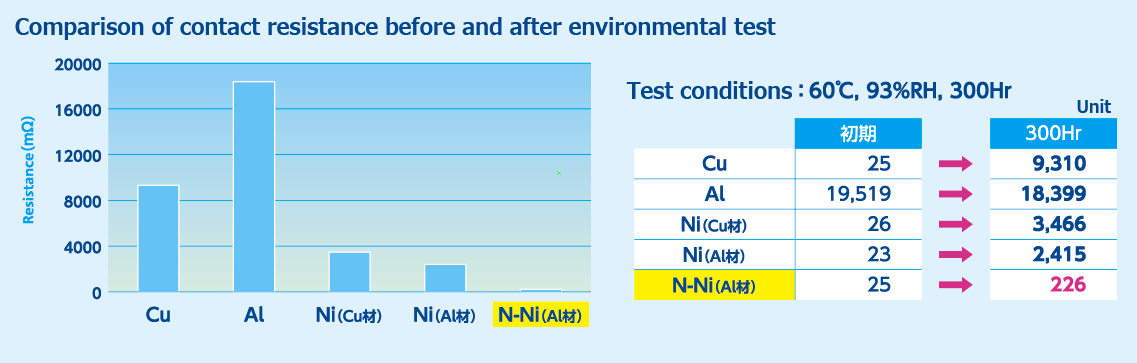

We have developed our own original N-Ni plating film to satisfy your demands. The “N” in N-Ni stands for Nishihara Rikoh. Our unique nickel plating suppresses contact electrical resistance increases due to deterioration over time more than conventional nickel plating.

It is possible to produce parts that can be used in conductive components while achieving reduced weight by using N-Ni plating for aluminum that is usually not suitable conductive metal.

New surface treatment technology which conforms to the conductive materials to be used in next generation automobiles is in demand. We conducted investigations, analysis and improvements of mechanisms to prevent nickel plating deterioration over time, keeping a close line of communication with the user, developing film with consistent evaluation standards as well as measuring methods and offering proposals on plating technology for conductive materials. This enabled us to realize mass production in a short period of time.

Technology combining N-Ni plating and aluminum materials not only makes for a lightweight product, but also has excellent cost benefits and opens a wide range of possibilities through the development of next generation product in industries such as automobils.

We offer analysis and evaluation technology from the viewpoint of the customer and provide support for product development so our customers can use our plating with a peace of mind.

N-NI is a registered trademark of Nishihara Rikoh (Trademark registration No. 6036013)

Related Links

Our mass production technology and quality assurance process enable hoop plating on aluminum materials

Plating on wider materials combined with slitting enable a stable supply of high-quality plating materials at an appropriate quantity and appropriate price.

By controlling the plating area, we optimize the electronic component product process.

We carry out solution analysis and film property analysis to maintain and improve plating quality.