Solving problems with wider material plating + slitting

Issue: Providing support for mass production of electronic components

The demand for electronic components has increased with the popularization of computers, cellular devices and flat screen TVs. Electronization and automation in automobiles have also been advancing in recent years, therefore the demands for on-vehicle electronic components is expected to further increase.

Functions to ensure automobile safety are supported by a wide variety of electronic components. Plating materials which are a part of these components require a high quality and stable supply. To achieve this, it is necessary to overcome the following issues.

- Variations in levels of quality in plating materials.

- Not being able to deliver plating materials at the appropriate time with appropriate amount.

- Plating material production capacity is lacking, cutting off the supply.

- High costs of high-quality plating materials

Nishihara Rikoh Solutions

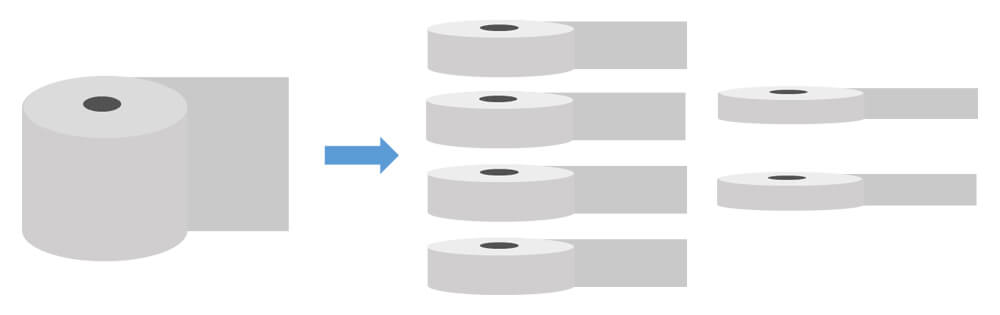

We offer wider material plating + slitting to overcome above issues. Multiple coils are created as if coped by hoop plated materials undergoing slitting with our highly knowledgeable plating material handling techniques, cutting wider materials into actual used range in the post-process.

We offer wider material plating + slitting to overcome above issues. Multiple coils are created as if coped by hoop plated materials undergoing slitting with our highly knowledgeable plating material handling techniques, cutting wider materials into actual used range in the post-process.

Combining wider material plating and slitting allows maximum performance of our hoop plating, enabling a stable supply of high-quality plating materials and appropriate quantity and appropriate price.

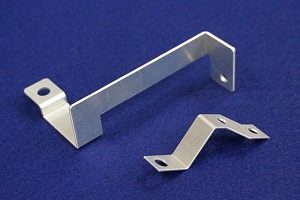

Please consider combining our own unique N-Sn and N-Ni plating with slitting in cases such as the following:

- Switching over from copper to lightweight aluminum is difficult due to little cost benefits and difficult evaluation.

- Tie-ups with reliable aluminum material plating companies in both quality and technical aspects.

- Concerns with future stable supply lines of aluminum materials plating.

- Considering lower cost aluminum materials.

- The need to improve quality of aluminum material plating.

Possible slitting size

| Material | Plating | Width[㎜] | Thickness[㎜] | Slit width[㎜] | Slitted rolls number |

| Cu Stainess steel Iron-nickel alloy(42alloy) |

Sn | 10~150 | 0.05~0.5 | 8.5~75 | 10 |

| Ag | 10~150 | ||||

| Ni | 10~120 | ||||

| Al | Ni | 10~250 | 0.1~2.3 | 10~240 | 20 |

| Sn |

Related Links

We provide hoop plating with stable quality at an inexpensive price.

N-Sn enables secure soldering and improves performance of electronic components.

Our mass production technology and quality assurance process enable hoop plating on aluminum materials.

N-Ni realizes technology optimal for conductive parts which require reliability over a long period of time.