Plating on Aluminium

Properties of aluminum

Aluminum (symbol: Al) is a lightweight metal that has good thermal and electric conductivity under normal temperatures and pressure, great processability, with high resistance to corrosion due to being susceptible to oxidation. Aluminum is widely used for items such as the one-yen coin, aluminum sashes, structural materials and heat sinks.

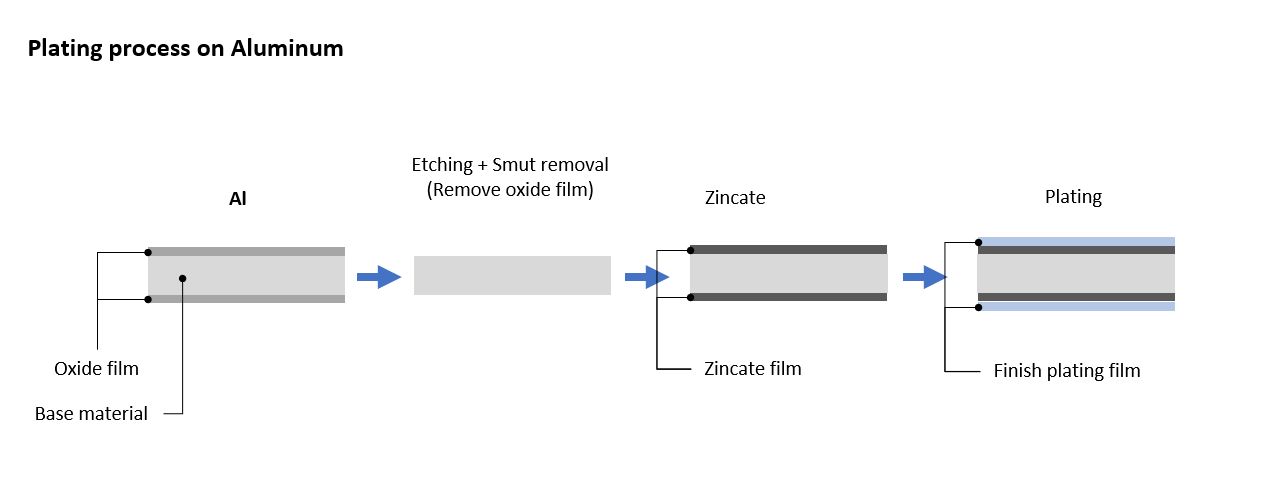

Plating on aluminum

Aluminum is popular for having favorable electric conductivity, being light weight and having a high resistance to corrosion due to generating an elaborate and stable oxide film in the air. It is starting to be used as a conductive material in the fields of electronics and energy.

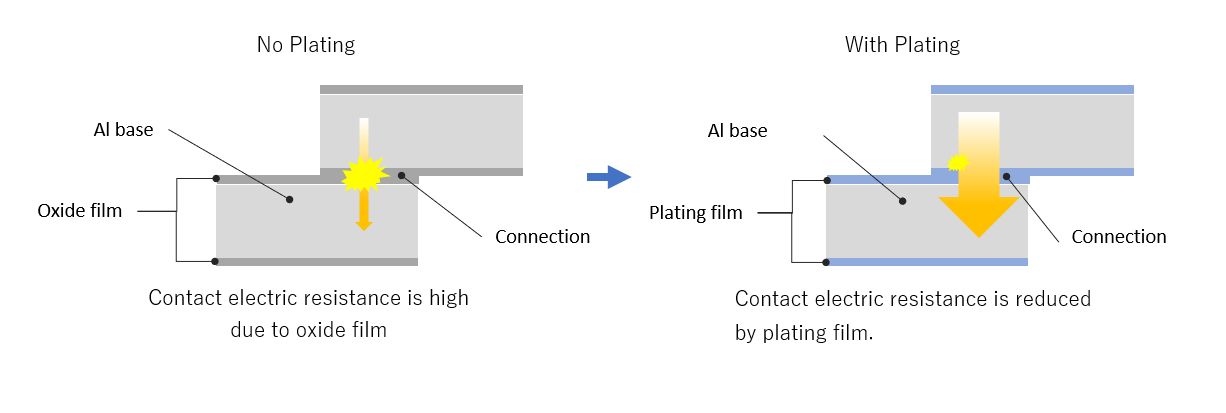

However, the oxide film can decrease processability when carrying out surface treatment. For example, when used as a conductive material, this oxide film increases contact electric resistance and connection parts generate heat which cause significant electrical loss.

Aluminum has long been considered a difficult material for plating. Currently, secure and stable processes have been developed for plating on aluminum materials which have had poor stability and adhesion, providing solutions to surface treatment problems

Major functions acquired from plating on aluminum materials

- POINT1

- Reducing contact electric resistance

- POINT2

- Increased solderability

- POINT3

- Improved workability in resistance welding

Reducing contact electric resistance

The aluminum oxide film does not conduct electricity well, therefore usage as a conductive material are limited. Although the electric conductivity rate of aluminum is approximately 60% inferior of copper, the specific weight is around 30% lighter which enables twice the current as compared to the copper at the same weight, making it extremely economical as a conductor.

| Category | Aluminum | Copper |

| Specific weight [g/cm3] | 2.7 | 8.9 |

| Electric conductivity [%IACS] | 64.9 | 100 |

In order to utilize these cost cutting benefits, our plating involves removing the aluminum oxide film, then plating metals with a low level of electrical resistance before the oxide film generates. Plating aluminum deceases contact electrical resistance and enables a lightweight conductive material.

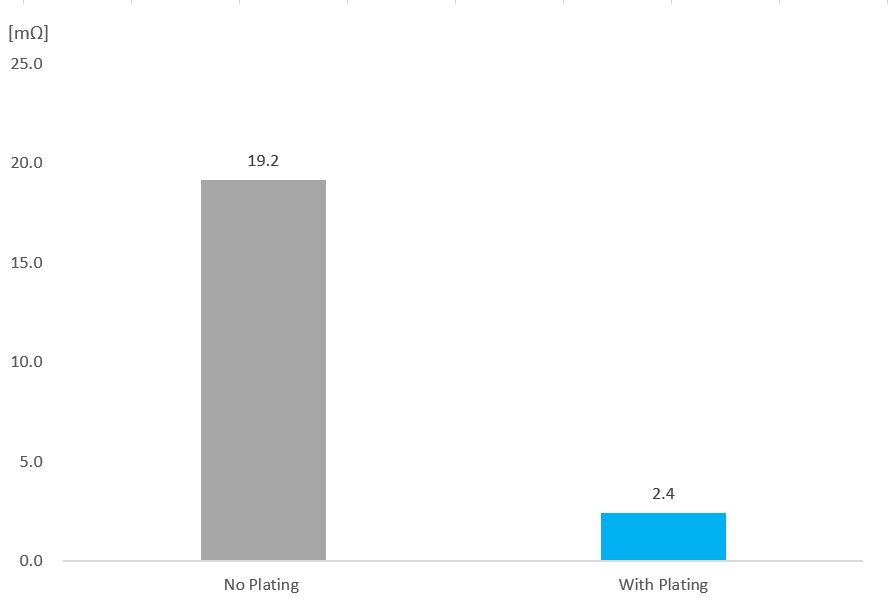

When comparing contact electrical resistance with specific weight of 0.5N, there is an 87.5% decrease.

Plated aluminum materials are perfect for jointing bolts while conducting a large amount of electricity such as in busbars. We recommend our own uniquely developed N-Ni for electricity contact usages.

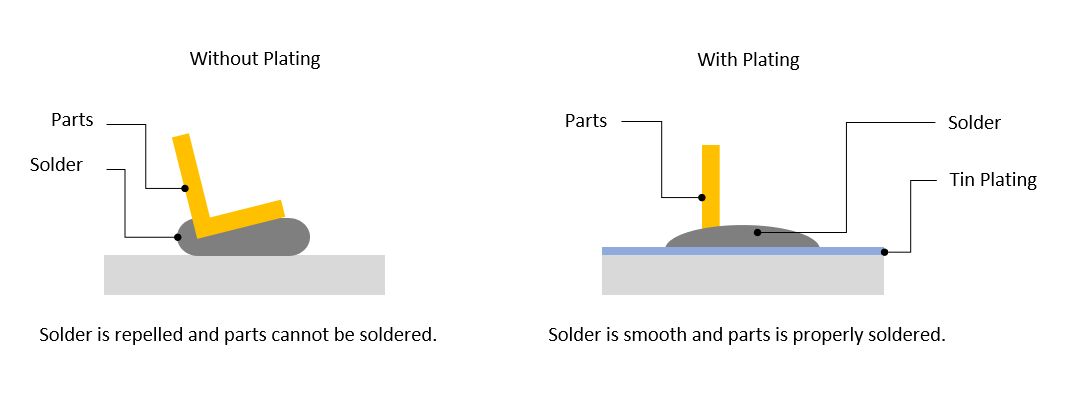

Increased solderability

Aluminum is susceptible to oxidation and repels solder. Generally, flax may be used to increase solderability but because most of them have a strong acidity, it poses the risk of penetrating the aluminum materials.

In addition, when using flax, it is necessary to implement a cleaning process after soldering and there is an impact on the environment as well as a burden on workers.

Aluminum often causes galvanic corrosion; therefore, direct soldering creates local cell action which makes it more likely for the soldered part to deteriorate.

Soldering to aluminum materials is possible by surface reforming by Ni + Sn plating which has long been adopted as preliminary solder plating.

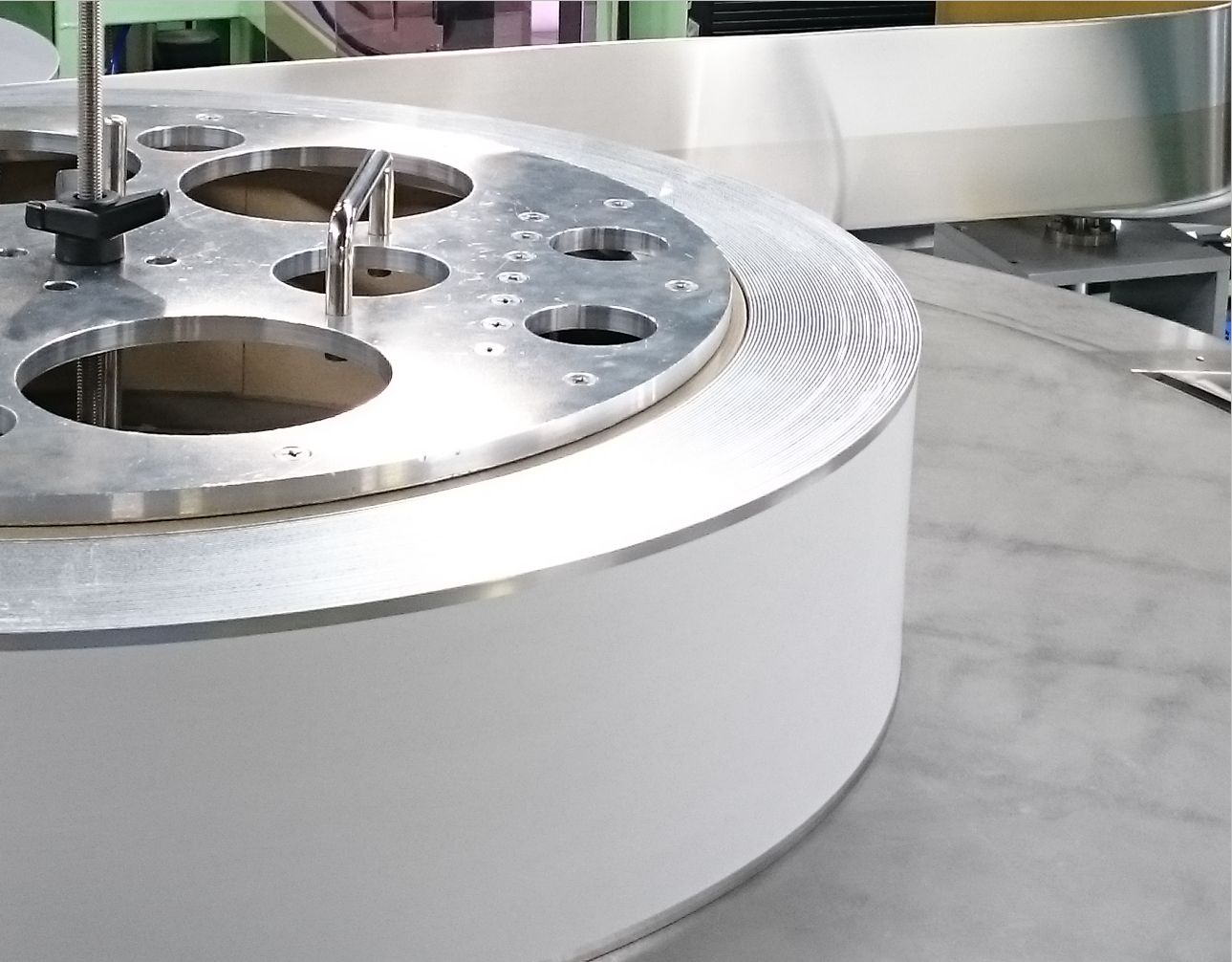

Improved workability in resistance welding

When welding aluminum materials with resistance welding, aluminum is adhered to the welding machine electrode and the welding strength decreases due to an increase in electrical resistance. Therefore, it becomes necessary to increase the frequency of electrode polishing which lowers work efficiency.

Plating on aluminum with Ni + Sn suppresses aluminum adhesion to electrodes which enables higher efficiency.

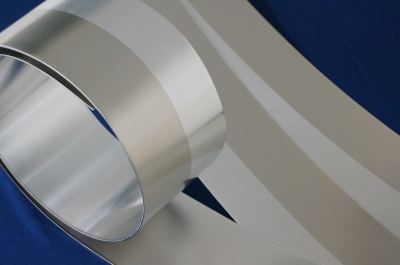

Features of Our Hoop Plating for Aluminum Materials

Plating materials which make up vehicle components require a high quality and stable line of supply. The demand for switching to lightweight plated aluminum materials from copper is increasing due to vehicle fuel costs and demands to improve traveling distance.

In order to meet these demands, we create a high quality and stable line of supply for hoop plated aluminum materials which requires both production technology and quality assurance.

Advantages of hoop plating for aluminum materials

- POINT1

- Stable quality at an inexpensive price

- POINT2

- Deliveries made at the proper time and quantity

- POINT3

- Optimizing material and film properties

Stable quality at an inexpensive price

Hoop plating enables consistency necessary for plating when compared to plating parts individually after molding, and allows for high productivity and decreases uneven quality.

We can provide the aforementioned functionality obtained through plating aluminum materials with stable quality at an inexpensive price.

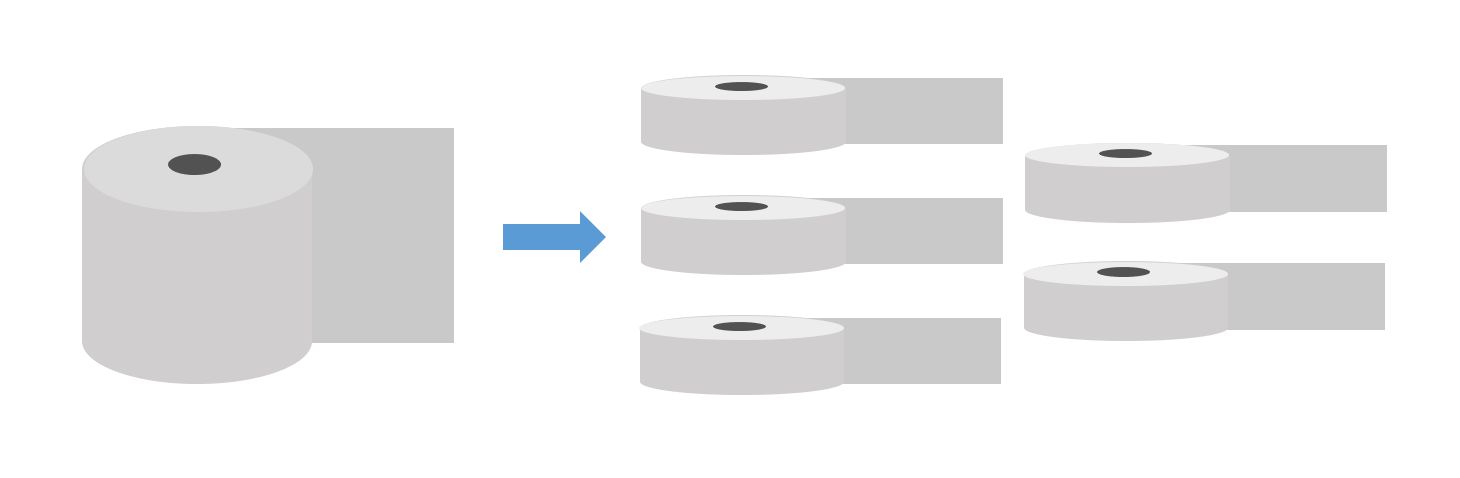

Deliveries made at the proper time and quantity

With the increase in demand for vehicle components, there may be cases in which it is not possible to deliver plated parts at the proper time and quantity, as well as cases in which supply is not possible due to a lack of production capacity.

By slitting materials which have undergone hoop plating, in a wider range than actual usage in post-processing, it enables a stable supply of high-quality plated materials at the appropriate quantity and price.

3. Optimizing material and film properties

There are cases in which plated area and aluminum base area are both required within the same part when designing components such as when plating cause defects in post-processing and areas which require plating properties combined with areas requiring base materials.

Partial plating can solve these problems. We offer support for partial plating even with hoop plating on aluminum materials, optimizing the production process of parts matched with stable quality.

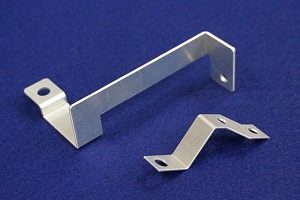

Products suitable for hoop plating on aluminum materials

| Usage | Recommended plating specifications | Effect | |||

| Lightweight | Contact electric resistance | Solderability | Weldability | ||

| Overall vehicle electronic components | N-Ni+Sn | 〇 | 〇 | 〇 | 〇 |

| IC packaging | N-Ni+Sn | 〇 | 〇 | 〇 | |

| Heat sinks, heat spreaders | N-Ni+Sn | 〇 | 〇 | 〇 | |

| LED | N-Ni+Sn | 〇 | |||

| Secondary batteries | N-Ni | 〇 | 〇 | ||

| Busbars | N-Ni | 〇 | 〇 | ||

Related Links

We provide hoop plating with stable quality at an inexpensive price.

N-Ni realizes technology optimal for conductive parts which require reliability over a long period of time.

N-Ni realizes technology optimal for conductive parts which require reliability over a long period of time.

Plating on wider materials combined with slitting enable a stable supply of high-quality plating materials at an appropriate quantity and appropriate price.