High-functional Tin Plating

Tin Plating

Tin (symbol: Sn) has a fusion point of approximately 232℃ and has been used for a long time because it is comparatively easy to refine and process.

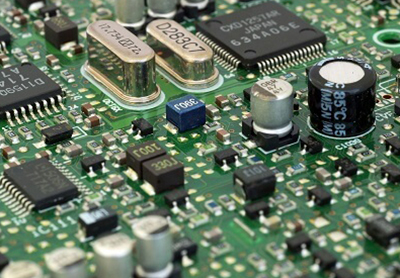

Tin is widely used for surface treatment as it is more abundant and less expensive than noble metals such as gold and silver. The wide range of usages include not only anticorrosion for base material, but also preliminary solder plating for soldering terminals such as electronic components to printed circuit boards.

N-Sn Plating

The N in N-Sn plating is the first letter “N” of Nishihara Rikoh. Our original and unique tin (Sn) plating is effective in preventing oxidation.

N-Sn plating on terminals such as electronic components can secure soldering improve performance of the electronic components.

Major functions and features of N-Sn plating

- POINT1

- Low level of wettability deterioration

- POINT2

- No aggregation

- POINT3

- No reflow discoloration

- POINT4

- Little increases in contact electric resistance

Low level of solder wettability deterioration

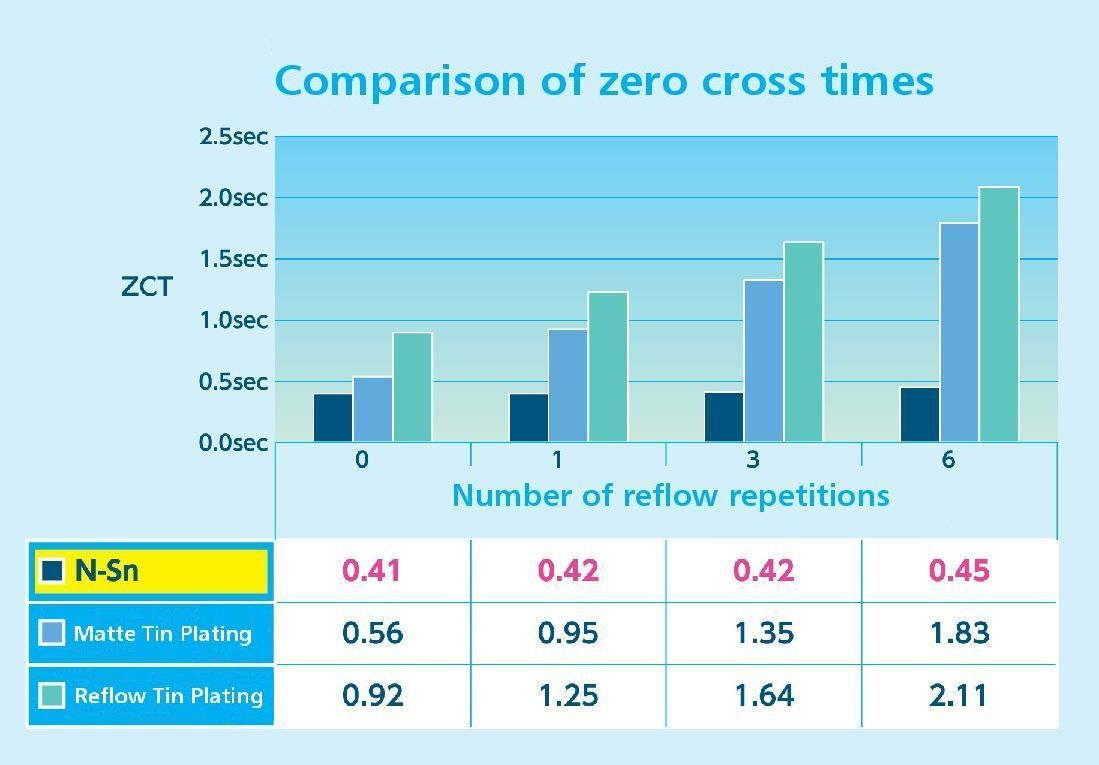

Generally, Sn plating (Matte Sn plating, Sn reflow plating) accelerates surface oxidation due to the heat during surface mounting, and causes solder wettability deterioration; however, N-Sn plating decreases solder wettability deterioration with anti-oxidation effects in the plate film.

As data measuring zero-cross time which displays level of wettability shows, there is no solder wettability deterioration in N-Sn plating even after multiple heat processes.

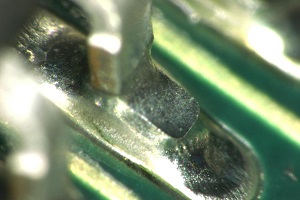

No aggregation

| N-Sn | Bright Sn |

|

|

N-Sn plating features even melting through heat during surface mounting.

The production involves limiting organic content in the plating film to one-tenth of Bright Sn plating filming.

This results in reduced aggregation in the film, which obstruct the mounting of parts.

C amount (wt%) in the film

| Bright Sn | N-Sn | Matte Sn (without discoloration prevention) |

| 0.050% | 0.004% | 0.007% |

No reflow discoloration

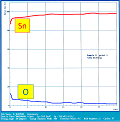

The general Sn plating film , melts due to the heat during surface mounting, organic substance accumulated in the film is separated and forms an oxide film layer on the surface.

As the oxide film layer on the surface becomes thicker, the exterior of the Sn plating film is seen to change color. The color gets darker as the layer gets thicker, decreasing the level of wettability.

A decrease in wettability leads to deterioration of reflow and can lead to serious defects.

N-Sn plating reduces organic substance in film, compared with Bright Sn plating. Therefore, it maintains a satisfactory reflow appearance (luster) without discoloration even under the harsh condition of 6 cycles at 270℃×30 seconds.

Test results

| N-Sn | Reflow discoloration test | Sn reflow | |

| Reflow discoloration test |  |

|

|

| AES analysis Red: Sn Blue: O |

|

|

|

| Oxide layer thickness | 6μm | 27μm | 27μm |

Due to the anti-oxidation effects of the film, the N-Sn platinge film maintains a top level of quality without oxidation in the film surface from the following reflow process even when undertaking the impact of burr removal after molding, bending after plating and surface damage.

Little increase in contact electric resistance

Oxidation on the platinge film surface increases contact resistance. The anti-oxidation effects of N-Sn plating enables suppression of increase in contact resistance and maintains connection reliability of electronic parts.

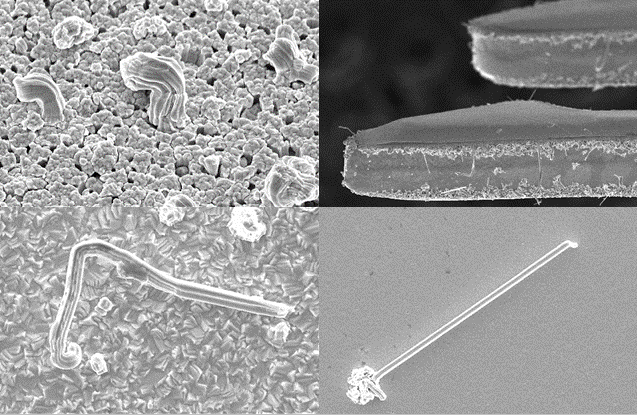

N-Sn plating tin whisker measures

Tin whiskers are a growth phenomenon of single-crystal tin metal fibers. It is considered difficult to be completely eliminated when using tin. We actively participate in whisker research and we provide ideas for reducing whiskers focusing on growth in intermetallic compounds based on the results of this research.

Combining the advantages of plating and base material.

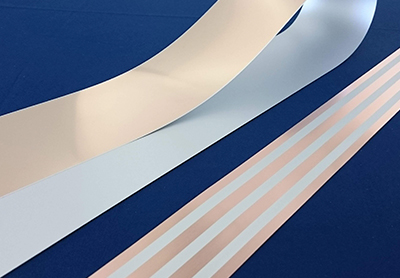

N-Sn plating can be used in partial areas as completely covering base materials.

Combining optimal base materials and parts designs enable hybrid usage of the superior N-Sn plating properties and base material properties which increase production efficiency of electronic components.

Construction of an efficient production system

N-Sn plating is produced in 3 locations in Japan under the same management system with the hoop plating system which enables mass production of stable quality, therefore dispel the idea that high functionality should come at a high cost. We offer a stable supply to our users at the proper prices and delivery times.

In addition, combining our slitting process and partial plating enables high functionality at low costs.

N-Sn is a registered trademark of Nishihara Rikoh (Trademark registration No. 6026014)

Related Links

N-Sn enables secure soldering and improves performance of electronic components.

By controlling the plating area, we optimize the electronic component product process.

We provide hoop plating with stable quality at an inexpensive price.