Solving problems with N-Sn plating

Issue ①: Completely removing lead from parts such as electronic components

Lead (Pb) is subject to environmental regulations and laws including the RoHS Directive and lead-free properties are demanded in electronic part materials.

大From the past, alloys of 60% tin (Sn) and 40% lead as well as 90% tin and 10% lead were called solder. These alloys had a low melting point and were easy to use, therefore were excellent for using over a wide range including soldering materials and preliminary solder plating when soldering metals. Since lead played an important role among its alloys, the following problems occurred in conventional lead-free preliminary solder plating.

- Lead-free tin plating film creates whiskers.

- Lead-free tin plating film often undergoes discoloration (oxidation).

- Lead is incorporated into tin as an impurity in the refining process so it is necessary to control the lead threshold level.

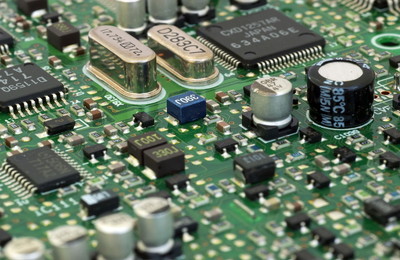

Issue ②: Miniaturization of electronic components and surface mounting

Various types of electronic devices are reaching higher levels of performance and miniaturized. The electronic components in these devices are also becoming more compact. Mounting methods to printed circuit boards have made the transitions from the through hole (flow) method to the surface mounting (reflow) method in order to increase mounting density. As a result, this has led to the following issues in conventional preliminary plating.

- Carbon contained in preliminary solder plating film turns into gas due to reflow heat and the plating film condenses causing aggregation. This leads to electronic components veering from the land pattern at the time of surface mounting.

- Preliminary solder plating surface oxidizes and solder wettability deteriorates which disables surface mounting.

- In order to mount electronic components on both sides of printed circuit boards, oxidation on the preliminary solder plating surface is accelerated while transporting to the surface mounting furnace multiple times causing reflow discoloration which considerably deteriorates solder wettability.

- Applying a film such as an anti-discoloration agent to reduce oxidation on the preliminary solder plating surface causes a rise in terminal contact resistance.

Nishihara Rikoh Solutions

We recommend our N-Sn plating as the optimal preliminary solder plating for surface mounting type electronic component terminals to solve the problems listed above.

N-Sn plating features

Plating film itself prevents oxidation

- Low level of wettability deterioration

- No aggregation

- No reflow discoloration

- Little increase in contact electric resistance

Using optimal plating and base materials

- Utilizing both the features of plating and base materials

Tin whisker prevention

- Preventing tin whiskers with proposals focusing on growth in intermetallic compounds.

Preventing impurities

- 100% pure tin anode

- Regular monitoring of threshold levels

※N-Sn is a registered trademark of Nishihara Rikoh (Trademark registration No. 6026014)

Related Links

N-Sn enables secure soldering and improves performance of electronic components.

By controlling the plating area, we optimize the electronic component product process.

We carry out solution analysis and film property analysis to maintain and improve plating quality.