Solving problems with partial plating

Issue ① Issues with terminals connecting batteries and printed circuit boards

An increase in electronization in a wide variety of fields such as household appliances and automobile wheels is rapidly accelerating. However, it is necessary to ensure a power source by soldering a battery terminal onto the printed circuit board in areas which did not have electronic control functions before.

Compact power sources are possible but the following problems occur with terminal connection.

- The connection between the battery terminal and printed circuit board is weak, causing disconnection which disables the power source.

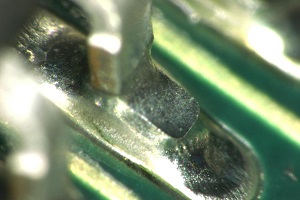

- Soldering the printed circuit board and terminal requires preliminary solder plating. However, connecting the battery and terminal is done through welding so plating obstructs the welding.

Nishihara Rikoh Solutions

Tin plating of reel-to-reel only on areas of terminal soldering covers the area including the press fracture surface with tin film, therefore enables stronger soldering. Nickel plating on areas connected to batteries through welding ensures a high level of welding.

Partial plating to stamped hoop materials was said to be difficult in the past. But now this has been realized through the development of our designated plating process.

Issue ② Optimal production of electronic components

With electronic devices being used in a variety of different fields, the demand for electronic components is diversifying. Automation of production is increasing and parts are becoming more highly functional for electronic component manufacturers so the demands for plated materials composed of these electronic components are diversifying. It is necessary to overcome the following issues to optimize the production of electronic components.

- When designing terminals, areas which require plating properties and areas which require base material properties exit within the same part.

- When designing terminals, areas exit which become defective if plated.

- When designing terminals, areas exit which become defective if plated.

- Terminals which require properties of noble metals have high cost.

Nishihara Rikoh Solutions

It is possible to apply partial hoop plating to only the necessary areas on the base materials. We offer proposals to reduce the amount of noble metals and combine the superior qualities of N-Sn and N-Ni plating with the qualities of base materials.

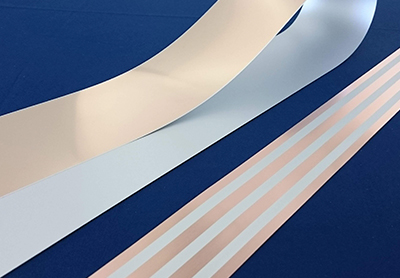

Partial plating

Plating on stamped hoop materials

| Finishing | Undercoat | Thickness[㎜] | Width[㎜] | |||

| Base material | Plating | Max thickness[μm] | Plating | Max thickness[μm] | ||

| Cu (Pure copper, Phosphor bronze, Brass or other alloy) |

Au | 0.5 | Ni | 5 | 0.08~0.25 | 6~50 |

| Sn | 10 | Ni | 5 | 0.08~0.8 | 5~50 | |

| Sn-Bi | 5 | Ni | 5 | 0.1~1.0 | 5~50 | |

| Stainless steel(SUS304) | Sn | 10 | Ni | 2.5 | 0.1~0.25 | 10~50 |

※Tolerance (SUS)

Liquid surface: Required dimensions ±1.0㎜ (Partial plating possible only with Sn plating)

Resistance: Required dimensions ±0.5㎜ (Partial plating possible only with Sn plating)

Plating on stamped hoop materials

| Finishing plating | Undercoat plating | Tone | Plating area | ||||

| Bright | Semi-Bright | Matte | Overall surface | Stripe | Partial | ||

| Tin | Nickel or copper | 〇 | 〇 | 〇 | 〇 | 〇 | |

| Tin-bismuth alloy | Nickel | 〇 | 〇 | ||||

| Gold | Nickel | 〇 | 〇 | 〇 | |||

| Silver | Nickel + copper | 〇 | 〇 | 〇 | 〇 | ||

| Nickel | none | 〇 | 〇 | 〇 | 〇 | ||

Related Links

We provide hoop plating with stable quality at an inexpensive price.

N-Sn enables secure soldering and improves performance of electronic components.

N-Sn enables secure soldering and improves performance of electronic components.

Our mass production technology and quality assurance process enable hoop plating on aluminum materials.