Continuous Plating

About Hoop Plating

Hoop plating is a process involving continuous high-speed plating on long strips.

Metal materials curled up in a roll or processed workpieces wrapped in a reel undergo pre-treatment and plating process continuously while being extracted, then wrapped again to complete the process. This is also called reel-to-reel plating or continuous plating.

Advantages of hoop plating

Stable quality at a reasonable price

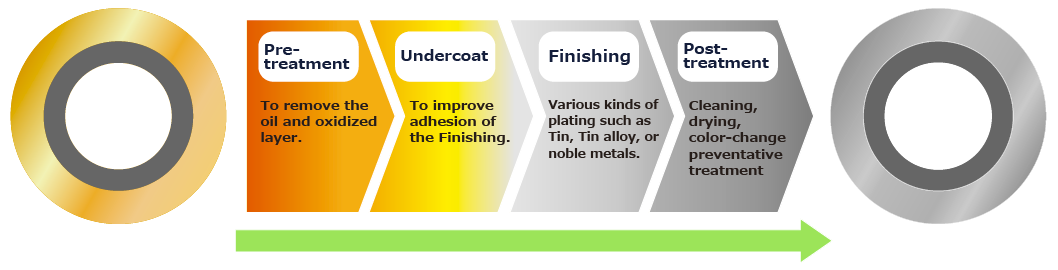

Compared to plating on workpieces after pressing, hoop plating has high productivity enabling consistent operation from pre-treatment, undercoat plating, finishing plating and post-treatment. Unevenness in plating thickness is very little, allowing for stable quality.

Better flexibility in part design

Long objects can be wound up in the pre-treatment (pressing, etc.) and inserted into the production line as a whole. Carrying out plating on strip and board materials beforehand allows for improved flexibility in part design such as layout design in pressing.

Partial plating with flexible design

Hoop plating features the ability to combine various processes with equipment design. Partial plating is possible in the areas of your choice with patterns such as stripes, spots and single surfaces by applying tape-masking in the process.

Mass Production Line

In our continuous plating line, the whole plating process and various pre and post treatments neccecary are done with great consistancy..

Available Plating Specs

Available Plating Specs

スクロールしてご覧になれます

| Base material | Finishing | Undercoat | Thickness[㎜] | Width[㎜] | ||

| Plating | Max thickness[μm] | Plating | Max thickness[μm] | |||

| Cu (Pure copper, Phosphor bronze, Brass or other alloy) |

Sn | 10 | Ni | 1.5 | 0.05~1 | 10~200 |

| Sn Reflow | 10 | Cu | 0.5 | 0.1~0.8 | 10~100 | |

| Ni | 1.5 | |||||

| Ni | 2 | - | 0.05~1 | 7~102 | ||

| Ag | 5 | Cu | 1 | 0.08~0.8 | 10~160 | |

| Ni | 0.7 | |||||

| Stainless (SUS304 or others) Iron-nickel alloy(42alloy) |

Sn | 10 | Ni | 2 | 0.05~1.0 | 8~102 |

| Sn Reflow | 10 | Cu | 0.5 | 0.1~0.8※1 | 10~100 | |

| Ni | 1.5 | |||||

| Ni | 2 | - | 0.044~1 | 10~102 | ||

| Ag | 5 | Cu | 1 | 0.044~0.5 | 10~160 | |

| Ni | 0.7 | |||||

| Al (A1000,A3000, A5000,A6000) |

Sn | 5 | Ni | 2 | 0.05~2.3 | 10~250 |

| Ni | 4 | - | ||||

Possible slitting size

スクロールしてご覧になれます

| Material | Plating | Width[㎜] | Thickness[㎜] | Slit width[㎜] | Slitted rolls number |

| Cu Stainess steel Iron-nickel alloy(42alloy) |

Sn | 10~150 | 0.05~0.5 | 8.5~75 | 10 |

| Ag | 10~150 | ||||

| Ni | 10~102 | ||||

| Al | Ni | 10~250 | 0.1~2.3 | 10~240 | 20 |

| Sn |

Plating onto pressed material

スクロールしてご覧になれます

| Finishing | Undercoat | Thickness[㎜] | Width[㎜] | |||

| Base material | Plating | Max thickness[μm] | Plating | Max thickness[μm] | ||

| Cu (Pure copper, Phosphor bronze, Brass or other alloy) |

Sn | 10 | Ni | 5 | 0.08~0.8 | 5~50 |

| Sn Reflow | 10 | Cu | 0.5 | 0.1~0.8※1 | 10~100 | |

| Ni | 1.5 | |||||

| Ag※2 | 10 | Cu | 0.5 | 0.1~0.8 | 9~75 | |

| Sn-Bi | 5 | Ni | 5 | 0.1~1.0 | 5~50 | |

| Stainless steel(SUS304) | Sn※3 | 10 | Ni | 2.5 | 0.1~0.25 | 10~50 |

※2 Tolerance for Leadframe: Plating side: 0.8±0.1㎜ Guide hole minimum pitch: 3㎜

※3 Tolerance for SUS: Level: Demand specs±1.0㎜ Resist: Demand specs±0.5㎜

Partial Plating

スクロールしてご覧になれます

| Finishing | Undercoat | Type | Plating area | ||||

| Bright | Semi-bright | Matte | Overall | Stripe | Partial | ||

| Sn | Ni or Cu | 〇 | 〇 | 〇 | 〇 | 〇 | |

| Sn-Bi | Ni | 〇 | 〇 | ||||

| Au | Ni | 〇 | 〇 | 〇 | |||

| Ag | Cu+Ni | 〇 | 〇 | 〇 | 〇 | ||

| Ni | - | 〇 | 〇 | 〇 | 〇 | ||

Related Links

N-Sn enables secure soldering and improves performance of electronic components.

Our mass production technology and quality assurance process enable hoop plating on aluminum materials.

This section gives examples of solutions utilizing our over 60 years of expertise and plating technology which undergoes continuous improvement.