Trial production results

It is necessary to carry out evaluation through trial production in order to clarify problems before parts are made into the final product. We listen to the voices of our customers, such as “This is what I want to do” and “This is what I am struggling with” during development stages. We offer support to determine the optimal plating specifications in order to maximize functionality of parts included in the final product.

Initial product development stage

Plating trial production of laboratory scale is carried out by hands.

It is not necessary to purchase large amounts of expensive materials as we can correspond to small lots. We can also handle short term requests.

Mass production trial stage

Even if there is no problem in the beaker scale, the same result may not be obtained when continuous plating process and equipment are established.

Nishihara Rikoh can manage start-ups in-house, from designing and manufacturing of plating equipment to mass production. By making the pilot line meet the requires for mass production, specific product characteristics and process evaluation are possible.

Process evaluation

We carry out detailed verifications at each stage from trial to mass production. This makes the validation data consistent. Feedback of data collected through trial production is contributing to the smooth transition to mass production.

Although trial productions are not only success, we will respond to your request with optimal proposals. Even if it is difficult to meet, we will develop technology, looking for ways which can satisfy customers.

Trial production examples

Here are a few trial production examples we have handled in the past.

Plating onto next generation battery parts

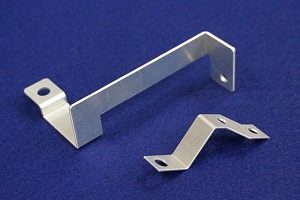

Plating onto metal

- Plating onto next generation battery parts

- Plating onto foil materials (up to t=15μm)

- Plating onto SUS436L materials

- Plating onto highly pure aluminum (3N)

- Plating onto aluminum wiring

- Making silver plating thicker (up to 100μm)

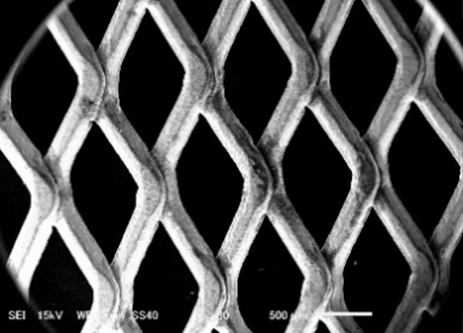

Plating onto carbon fibers

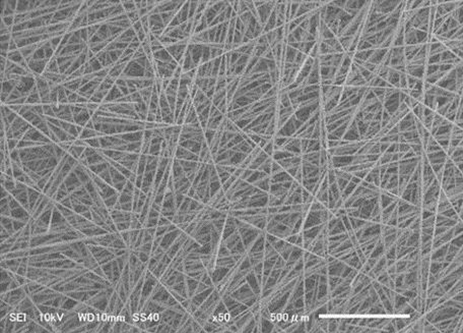

Plating onto resin etc.

- Electroplating onto carbon fibers

- Electroless Plating onto PET fibers

- Plating onto non-woven fabrics

- Plating onto paper

- Plating onto resin (PEI,PET)

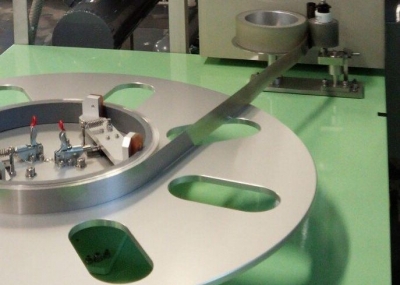

Hoop alumite equipment

Equipment establishment

- Hoop alumite treatment

- Roughening copper materials in the continuous processing line

- Gold plating peeling

- High precision partial plating (flexibility and precision)

- Resin coating on aluminum materials

We also offer technical support, including overseas.

Related Links

N-Sn enables secure soldering and improves performance of electronic components.

Our mass production technology and quality assurance process enable hoop plating on aluminum materials

N-Ni realizes technology optimal for conductive parts which require reliability over a long period of time.

We carry out solution analysis and film property analysis to maintain and improve plating quality.